How to Dye the Concrete Floor

Is the concrete always grey?Can we apply color to concrete?

Xingyi's sales team arranged a small training to show you how to make the concrete more colorful and shinning yestoday.

Here is the process,tell you how to dye the concrete step by step:

1.Before you dye the concrete floor,you should check the surface conditions first.After checking,grind with the High efficient self-propelled concrete grinder 800-4A and metal grinding shoes HTG-2Y 30#,60#(make sure the surface on which the stain will be applied is clean,free from unwanted defects,holes,hollows and glues ready for coloration.)

2.Clean the floor to clear the dust of surface

3.If there are holes or hollows on the surface,you should repair it first. Repair with HTG EC-1008 curing agent and Repairing cement,then grind with metal grinding pads HTG-2Y 100#.

4.Grind with Resin pads HTG C310 50#,100# (Please remember that be scrupulous with surface preparation to ensure removal of contaminants or defects that could ruin an otherwise beautiful staining job.)

5.Hardening with densifier HTG EC-N01,polish with resin pads HTG C310 50# to 200#.

6.Clean the dust on the surface and make sure the surface is completely dry.

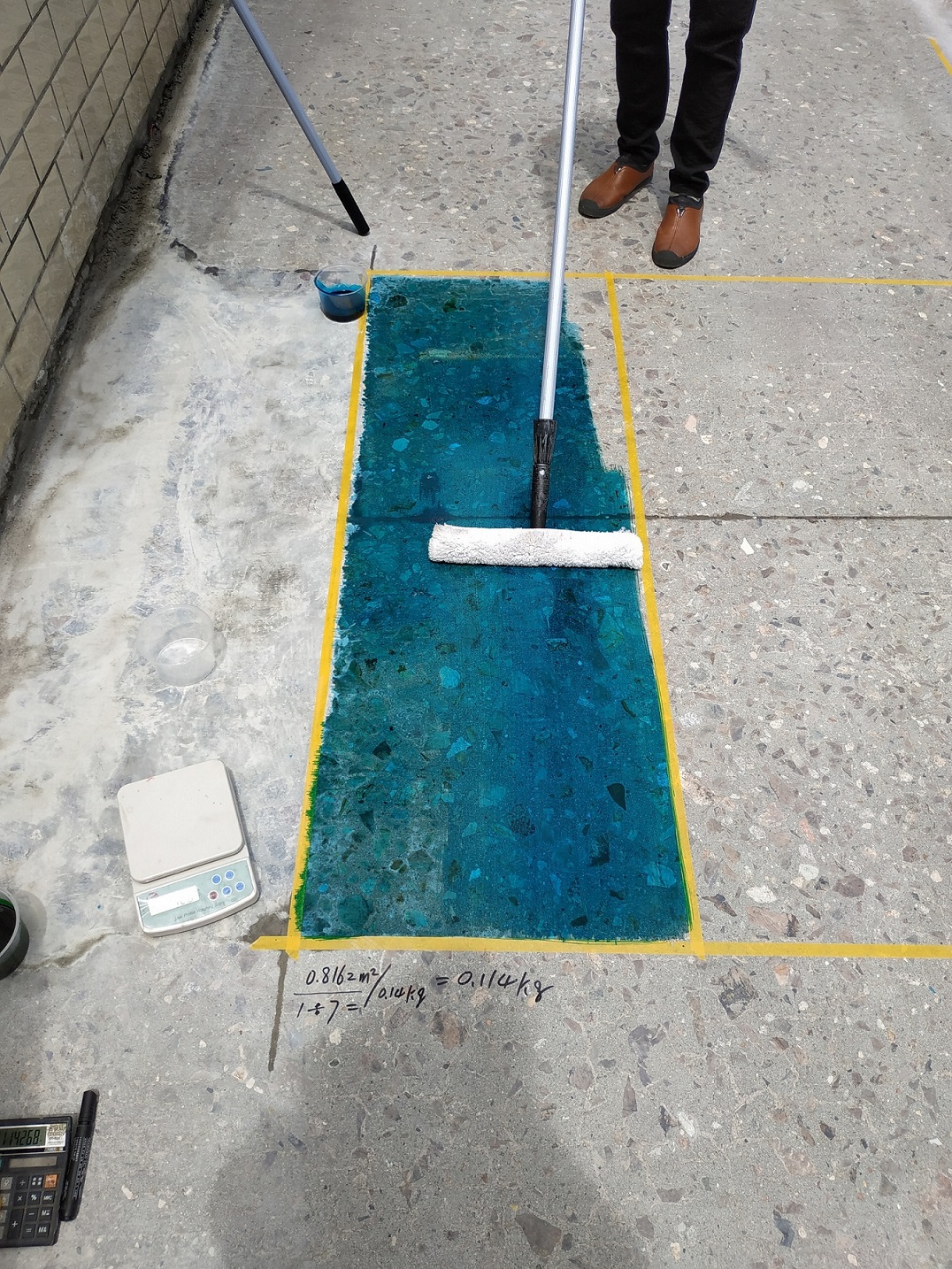

7.Concrete coloration preparation:1.calculate the area of the ground which is applied to be dyed and the amount of the coloring agent,then weight out the coloring agent.

■The coverage of osmotic type is generally 7square meters per 1kg that is 0.14kg/sqm,

another type is ionic agent generally is 1kg that can be used about 5 square meters,that is 0.2kg/sqm.

■According to the type of the coloring agent,osmotic agent for example,the amount of the coloring agent is the floor area times 0.14kg/sqm.

■PS: Dyeing agent CD-01 is the type of osmotic, the dyeing time is usually half an hour to one hour.

Dyeing agent CD-02 is ionic agent, drying time is usually 2 hours or more.

The optimum dyeing temperature is generally around 10 degrees Celsius.

8.Pour the stain color evenly on the surface and use a dust pusher to push come and back until the color is sufficiently stained.

9.Wait 4 hours at least to let the surface dry completely.Polish with concrete grinding machine 800-4a and resin pad C310 400#,

then clean up the surface.(Cause we dye the concrete outdoor and sun is shining,temperature is high,we just wait half an hour,we don't advocate doing like this,is not good for quality.)

10.Use half of the original dyeing agent to stain color again,and wait 4 hours at least.(The rougher the surface,and the better the effect,so if the condition and time allow,I suggest you can dye twice,this will work better and last longer.If it is not,it's better to dye the floor after buffing with resin pad C310 400#.)

11.Clean the dyed floor surface after drying with the washing machine to clear the dust and Residual agent.

12.Polish with the floor grinder and polisher 800-4A and resin pad C310 800#.

13.Clean the surface to clear the dust,then buff with high speed polisher HP27S and buffing pads HTG-DIP-HD027 1500# to clear the dust on the surface.

14.Apply color fixing and hardening agent CD-03 and open with a dust polisher evenly.At the time when color fixing and hardening agent is going to dry but haven't dry completely,buffing with high speed polisher HTS-HP27S and buffing pads HTG-DIP-HD027 1500# until the surface is hot and fully dry.

15.Spray with sealer EC-S02 and buff with high speed burnisher HP27S and buffing pads HTG-DIP-HD027 1500# until the surface is glossy.

Derechos de autor © 2015-2026 Fujian Xingyi Intelligent Equipment Co., Ltd.Todos los derechos reservados.dyyseo.com

Enlaces amigos :

distributed control system